03 Jan RENDERING: BEYOND BLUEPRINTS

The three principals of Missoula, Montana-based Hone Architects + Builders have much in common. They grew up in families who built anything from sheds to shelves and houses from scratch. They’ve all been out in freezing weather working as timber framers. And all are into sports and the great outdoors.

Fir and steel create a mood in the living room. The built-in shelving and mantel are reclaimed fir, and the fireplace is concrete and plaster.

Both Chris Chitty and Damian Mast quickly lost interest in higher education. Mast set out to be a wildlife biologist, assuming that would mean working outside. But it turned out to be mainly a statistics-collecting, tied-to-a-desk endeavor. Chitty studied engineering, but that wasn’t his passion — rock climbing was. He moved around a lot in his 20s and found carpentry was a good, portable way to make a living. (He and his wife moved to Missoula in 2008.)

The public areas of the home are filled with natural light and walls with ample room for the clients’ art collection.

Lucas Dupuis graduated summa cum laude with a Master of Architecture degree from Montana State University in Bozeman, but he was a bit disillusioned, and he, too, ended up framing houses for a couple of years. That is, until he became fed up with the hardships of the job and remembered he had a degree in architecture.

Daltile porcelain flooring creates a seamless flow from inside to out. The porch extends outward to capture sunlight in a relatively dark site.

For a number of years, the three worked together periodically on an informal basis. “The group of rock-climbing carpenters in Missoula was small enough so that Damian and I just started working together fairly naturally,” says Chitty. Mast had opened his then one-man firm, Mast & Co. Builders, in 2006. By the time Chitty joined him as a partner in 2013, he had four employees.

Adjacent to the mud room and gym, a custom cedar sauna is a welcomed retreat after a day of skiing or mountain biking.

Once he’d abandoned timber framing as a viable career, Dupuis worked at a local architecture firm but found the experience unsatisfying. At the height of the recession, he quit to open his own firm. His explanation? “I had a pass to Snowbowl (the local ski area),and I was done.

The kitchen and dining room spill out onto the upper patio. The clients love to cook and entertain. Along with pendant lights, a tape light at the perimeter beams gives the ceiling a glow. A cherry butcher block island holds the clients’ cookbooks.

“I had the opportunity to be self-unemployed for a while,” Dupuis says with a laugh. “And that’s when I met Damian. So we were self-unemployed cohorts eking out a living.”

More importantly, he adds, “I’d always had a calling to build things myself. I’ve always wanted to know how things work.” He went on to open Sustainable Building Design, LLC, and occasionally designed homes for clients of Mast and Chitty. He also became a certified energy efficiency consultant and spent about 30 percent of his time educating other architects and builders on compliance and energy efficiency. His entire practice was focused on sustainability.

The interior is infused with a sense of whimsy and humor. A center staircase allows mid-level access and a quick exit for dog walking.

“So our reputations grew independently and somewhat intertwined as people in this area learned about us [and sought us out if they] wanted something unique, like a timber-frame or an energy-efficient house,” Dupuis says. “We were all interested in the same things. And I could be there in real-time and see what was working and what wasn’t, and that was satisfying. We ended up together in 2019 and said we should all be just one happy group and do it all together.”

The Linden House clients sought a crisp, clean farmhouse style that would be warm and whimsical in Missoula’s Rattlesnake neighborhood. Hone helped them to split and modernize an old house to fit their needs. The exterior is locally sourced white wood and lime plaster, with Zola triple-pane European-style windows.

The trio opened Hone Architects + Builders in 2020. Today, the firm consists of a staff of 15, including three architects, a project manager, and 10 carpenters, along with an office manager.

“One of the reasons we came together is that we individually had frustrations with how projects were getting done,” Chitty says. “Damian and I would get a great client, and then we’d be like, ‘Now I guess we have to go find an architect.’ We didn’t have architects bringing us work; we just had clients come directly to us. And it was never satisfying to hand your client off to an architect without any idea what was going to happen when they came back to you with a plan. And once we started working with Lucas, it was a much more sensible experience to have him work with us early on, and really, it’s a question of him valuing the construction process and us valuing the design.”

In the kitchen, a locally sourced fir ceiling and reclaimed resawn beams contrast with white oak floors. The walls are Diamond white plaster. The maple butcher block island and custom vertical-grain fir cabinets are made by Bruce Allen Woodworks.

The team has a regular protocol for moving clients from one stage to another. First, they discuss the clients’ wants and needs. “We’re discovering who you are, and you’re discovering who we are,” Dupuis says. “We leave it pretty open. Maybe it’s writing a poem about what your ideal place is.”

Custom built-in shelves of vertical-grain fir hold the owner’s record and plant collections.

Budget is an important aspect of this initial phase, since people often have unrealistic views of what their budget will cover, as well as the mistaken impression that building in Montana will be inexpensive. It’s not. It won’t be as expensive as, for example, California, but it costs considerably more than building in Texas.

The Kebony wood deck off the owner’s suite looks over the backyard, where a plunge from Soake Pools shares space with a sauna and pool house. The sauna is sided in cedar with a corrugated black metal roof.

Once the clients and the team are comfortable, the second phase is research. They study the site, noting any issues or regulations that might affect the budget. The team then incorporates what they’ve gleaned from phase one into two or three broad schematic concepts, and the budgetary pros and cons of each are discussed.

The vaulted primary suite features a custom ladder by D.A. King Wood Works and has views of Waterworks Hill, one of Missoula’s many preserved open space areas. The triple-paned windows are from Zola, and the wood ceiling is from RBM Lumber.

Phase three begins with an agreement on the concept, budget, and timeframe. This is the time for details. What kind of windows, doors, finishes, and exterior materials do the clients want? Then, a final design is presented.

Once construction begins, clients receive a monthly statement outlining expenses, and they are consulted throughout the process on details. Then, several weeks after construction is complete, the team will return to address any issues the clients have.

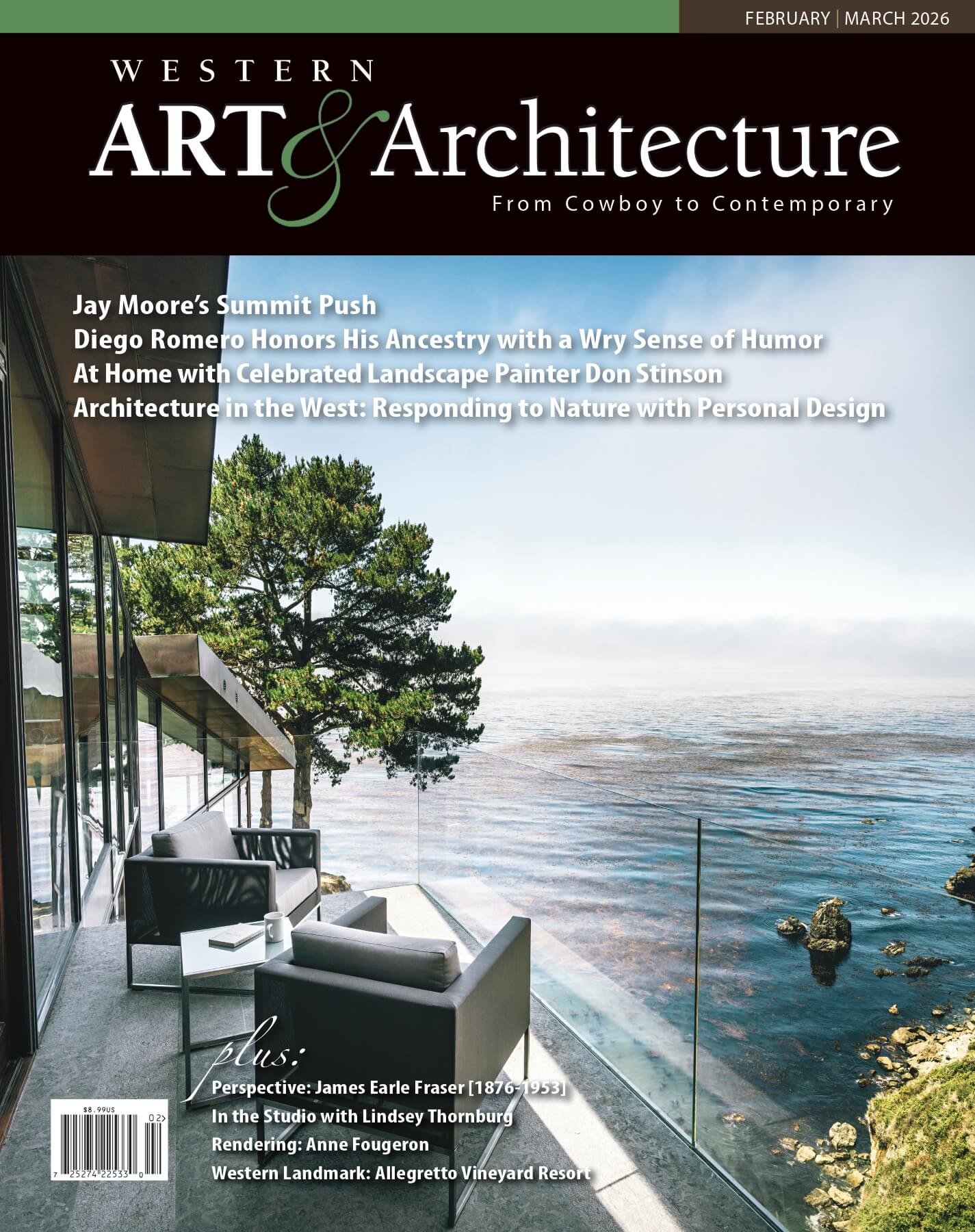

The clients for Rattlesnake Creek partnered with another couple to buy the riverside land, and protecting the riparian site was essential to the project. The rough-sawn reverse board-and-batten siding will age to gray. Triple-pane windows and double-stud walls contribute to the high-performance envelope. The house comprises three connected volumes that allow the landscape to dominate.

“What solidified all of us being one business is that the building process benefits when the architect draws a really accurate set of plans,” Chitty says. “And then the architect doesn’t have to draw more to get the project done so that everybody’s working on the same team to get the product to the client at the best value possible. Then everybody’s financial incentives align.”

For eight years, Mast and Chitty have been experimenting with prefabricated elements. “If you live in Montana, you can’t just dig a foundation and pour concrete any time of the year,” Mast says. “So we thought, hey, we’re going to do something for the carpenters’ winter; we’re going to set up shop. We’re going to build all the walls for this project and have them ready to go by the time the foundation’s dug. But we’re just framing walls. Nothing crazy.”

A steel beam divides the kitchen from the vaulted living and dining area. Playing with volume allows for both continuity and a different sensibility in each space.

The walls are then trucked to the site and installed by crane, which is particularly handy in more remote areas. “If we can use prefabrication as a way to build in controlled environments, where machines can do more of the brute force work, carpenters can keep at it longer,” Mast says. “We can be specialists, as opposed to climbing on a roof in February. So I think that’s one of the biggest reasons we’re interested in prefabrication is the ability to use a smaller, more skilled workforce.”

In the living room, corner windows provide views of the creek and glimpses of Mount Jumbo in the distance. High windows frame the greenery while protecting it from the neighbors. The built-in bench and floating shelves were created by Hone.

Of course, that doesn’t come at a lower cost, and to continue down this road, Hone will have to scale up their production facilities. But they love a challenge. In the meantime, they’re busy with custom homes. “We talk a lot about energy efficiency, and it’s an interest of ours,” Mast says. “But we’ve never really marketed that specifically. We try to make beautiful structures that attract people, and the rest just comes in.”

A glass-enclosed entryway ensures a warm welcome to a home that overlooks a creek and takes design inspiration from its setting.

Chitty is also active with ProHousing Missoula, which is addressing the city’s housing shortage and pushing for the 2025 rezoning of the city to include more walkable communities with cafes, shops, and a variety of income-level homes in areas that were previously zoned for expensive, single-family-only houses.

Protecting the sensitive local ecology dictated the placement of the house.

Today, Hone is known for its beautiful designs in a Scandinavian-influenced version of Rocky Mountain Modern and for energy-efficient elements like recycled wood, triple-pane windows, and double-stud walls. Their houses are crisply designed but also warm and comfortable, with clean air. There’s also a touch of wabi-sabi, for instance in the recycled wood, expressing beautiful imperfections and the history of handcrafting.

A white birch plywood loft keeps the den at the top of the stairs warm and light. Each turn of the house provides a new view. Both the custom built-in desk and steel railings are by Hone.

“The philosophy of whatever we design,” Mast says, “is we’re going to express the structure using honest materials and create a place that’s as enjoyable to live in as it is to look at.”

Writer and editor Laurel Delp is a frequent contributor to WA&A and other magazines and websites, including Town & Country, Departures, Sunset, and A Rare World.

Based in Missoula, Montana, Chuck Collier Schmidt takes pictures for clients throughout the Northwest. For the last 15 years, he’s specialized in photographing homes, buildings, and interiors, and his images have appeared in such publications as Architectural Digest, The New York Times, and Washington Post, among others; chuckcollier.com.

No Comments